Concentrated

Concentrated

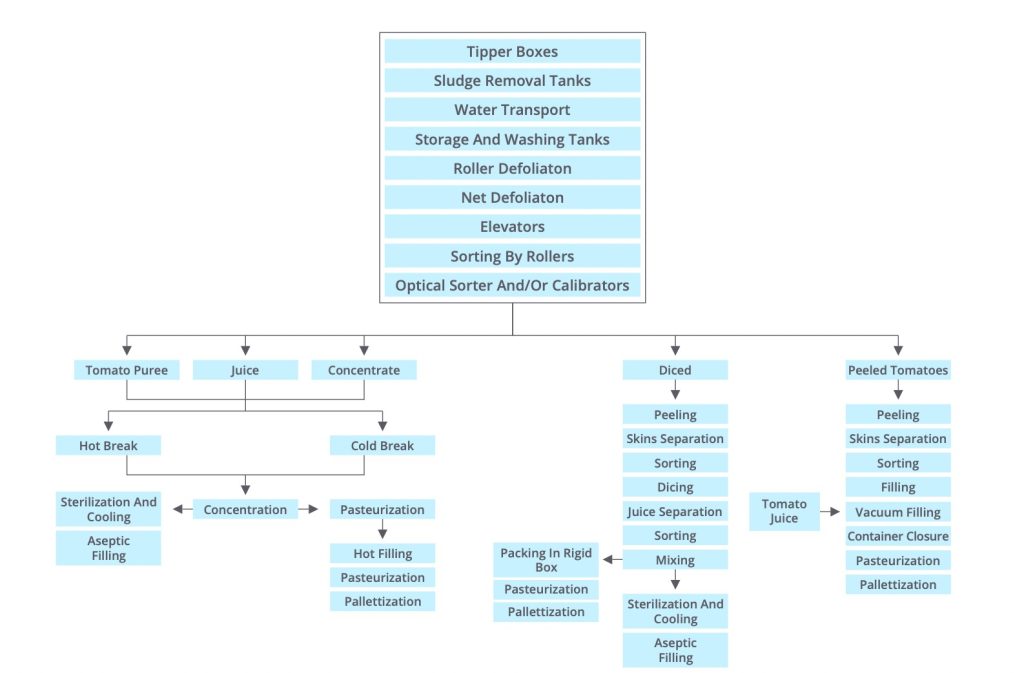

Tomato is used in the processing industry for a

wide range of derivatives: juice, purées, concentrates, peeled, pulp and diced. The collection, transport and transfer of the raw material are fundamental links in the industrial transformation of the tomato. The factories receive the raw material in bins that are overturned by tipping bins, and the tomato falls into tanks filled with water.

The first phase includes washing and sorting, essential operations to eliminate foreign substances (bodies) and unsuitable fruit. For the preparation of pureed and concentrated juices, it is necessary to grind the fruits, separate the seeds and skins and then, with the exclusion of the juices,

the more or less partial elimination of the constitution water. The term is reserved for preserves prepared by eliminating part of the water from the pulpy juice, obtained by shredding fresh fruits and sieving the shredded. All products with a minimum dry residue from a minimum of 12% to a maximum of 55% (net of added salt) are concentrated.

After shredding, the tomato is sent to a heat exchanger (scaldatrice or bovatrice) where it is subjected to heating. There are also hot-break systems with preliminary deaeration of the tomato (to facilitate the detachment of the peel in the subsequent extraction phase). At this point the shredded product is sent to the pass / refining unit.

This phase has the purpose of separating the skins and seeds while providing extraction and refining at the same time.

The juice is then collected in a stainless steel tank which serves as a lung to feed the subsequent concentration phase. The partial elimination of water is carried out by vaporization in the evaporators, of which there are different types.

Finally, we move on to pasteurization and filling. It is also possible to temporarily store the concentrates in special drums and stored in refrigerated cells or by aseptic packaging (product pasteurization – cooling – cold filling, in sterile conditions, in a sterile container).